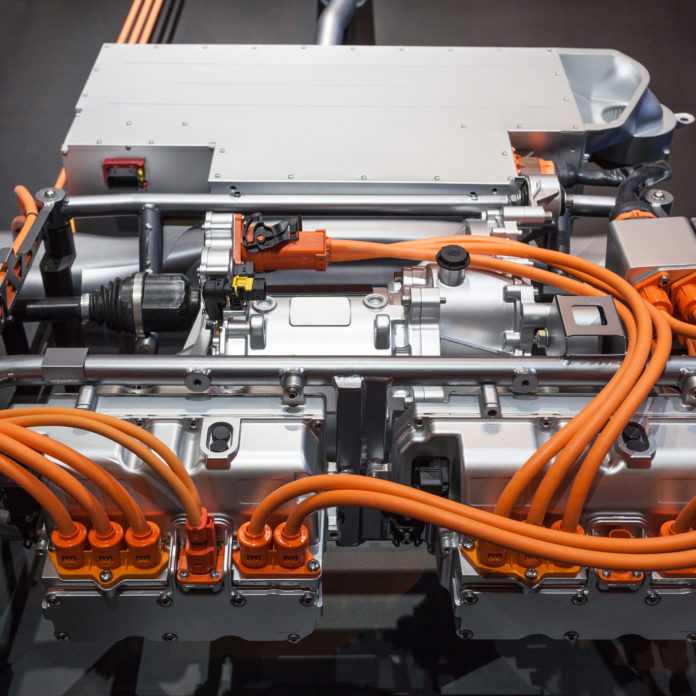

Flexible ISO-19642 Battery Cable Development

The challenge: To develop a next-generation 150°C XLPO high-voltage battery cable with ultimate flexibility, robust thermal compression characteristics, ISO-19642 conformance, and the ability to strip cleanly and consistently with no paper separator. Project background: North American vehicle manufacturers were experiencing two issues caused by battery cables that did not possess enough flexibility. First, slow production [...]