Materials science, electrical and mechanical engineers at work.

Our technological approach:

- Enhanced material performance

- High value solutions

- Creative, custom innovations

Our technology

We are a world leader in irradiated cross-linked technology and polymer science.

We are capable of creating wires and cables of superior durability, flexibility and thermal resistance. We are dedicated to regularly modernizing and developing our technologies and capacities to maintain our position at the forefront of the industry and to ensure our customers’ complete satisfaction.

Insulation technology

Our polymer scientists specialize in developing insulation materials that enable our customers’ wires and cables to withstand even the most extreme hot and cold temperatures for unprecedented durations. Their unique custom compounds are highly resistant to abrasion while maintaining flexibility and can handle higher rated voltage with thinner insulation.

Irradiation technology

Electron beam cross-link technology enables us to enhance insulation material performance, changing insulation material from a thermoplastic to a thermoset. Our eight irradiation units are capable of cross-linking wire from 26AWG to 700MCM (0.14mm2 to 350mm2) and cables with diameters up to 1.5 inches (3.8cm). Unlike other cross-link technologies, irradiation cross-link products are easy to cut and strip. Cable design and size are not limited.

Irradiation benefits and features

- Higher temperature resistance

- Thermoset (will not melt)

- Increased tensile strength

- Increased abrasion and cut through resistance

- Increased crush resistance

- Increased chemical and oil resistance

- Increased shear and compressive strength

Cross-linkable compounds

Including but not limited to:

- EPDM

- PVDF

- Nylon

- PVC

- Tyvrin

- Halar

- Neoprene

- Polyethylene

- Silicone rubber

- Vamac

- Nordel

- Polyurethane

- ETFE

- Viton

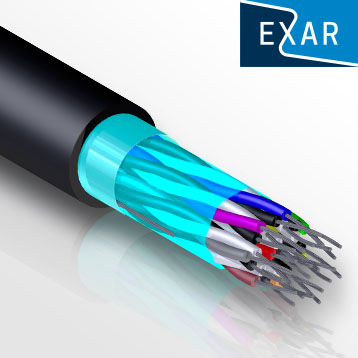

EXAR® technology

EXAR® utilizes irradiated polymer science, including low smoke zero halogen formulations, to create lead wires that perform well in extreme processes. Many motors and transformers are produced using varnish impregnation and bake technology. The EXAR motor lead wires are subject to exposure to varnish and temperatures up to 250°C for four hours. They survive this process and do not crack after the varnish is cured, thus reducing or eliminating costly rework and scrap.

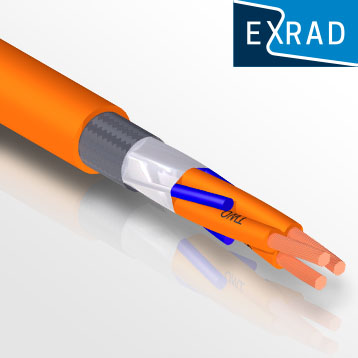

EXRAD® technology

EXRAD® products by Champlain Cable have been field proven in commercial vehicles and automotive applications over the past 20 years. Our design and development team use state of the art technology to design and produce cost effective wire and cable for the commercial vehicle market.

DATACLEAR® technology

DATACLEAR® technology utilizes the irradiated polymer science, focused on “Zero Halogen Content”, coupled intricately with “Low Smoke” formulations to create wire and cable products that will sustain performance during extreme, adverse environments. DATACLEAR products are designed to assist our Navy and NATO fighting Men & Women stationed on U.S. Naval vessels. DATACLEAR products have been tested to sustain themselves in direct fire and/or submergence in seawater while providing continuous operation of critical path systems. DATACLEAR products are the preferred choice by the U.S. Navy and trusted NATO partners for secure, reliable data and voice communication systems.

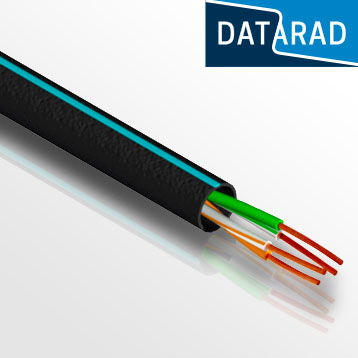

DATARAD® technology

DATARAD® technology utilizes the unique properties of Champlain Cables irradiated cross-linked polymers. DATARAD is well known as a 125°C and 150°C rated lead wire for powertrain applications. Unlike other powertrain wire insulations such as XLPE’s, PVC, EPDM, etc., DATARAD polymers have excellent dielectric properties making a great high temperature insulation for Automotive and Commercial Vehicle Ethernet applications. Our unique electron beam cross-linking and polymer science combined with our electrical expertise and repeatable processes provide provides the best yields the best automotive and commercial vehicle ethernet cables available.