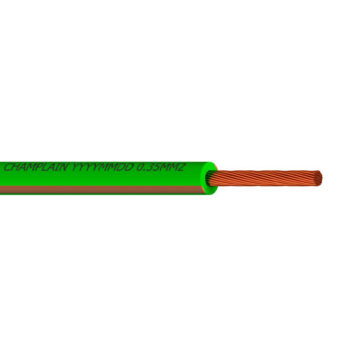

EXRAD® ERGOFLEX 125 ISO 19642-3 Class C Thin-Wall High-Flex Door Wire

-

Product features:

- Door & Hatch Applications

- Long Flex Life

- Low Temp Flex

EXRAD® ERGO FLEX 125 is a high-flex door and hatch wire designed specifically for flexibility and long flex life, even in cold temperatures. The temperature performance range of EXRAD ERGO FLEX is –70°C to +125°C, well beyond the failure point of conventional wires. Standard connectors match exactly and seal well with this wire because it is the same size as other common automotive conductors.

Even though it is flexible, EXRAD ERGO FLEX has enough column strength to allow easy insertion through the seals of water-resistant connectors. The high temperature performance and fluid resistance means it can be routed throughout the vehicle including the engine compartment. Superior abrasion and pinch resistance ensures durability and helps keep the wire harness safe and free from defect even with hundreds of thousands of flexes.

Given today’s longer warranties you need a wire that will perform more bends and twists than ever before. EXRAD ERGO FLEX provides up to 9 times more flexing than conventional wire. The end result is an automotive wire ideally suited to applications where a combination of flexibility, long flex life and performance is required.

- High Temperature Rating: 125°C

- Low Temperature Rating: -70°C

- Voltage Rating: 60V

- Flame Resistance: FT-2

- Oil Temperature Rating: 60°C

- Ultraviolet Resistance: Black

- Radiation Resistance: No

- Flexibility Rating: 4

- Fluid Resistance Rating: 4

- Cut-Through Resistance Rating: 3

Specifications

| Product

Number |

Standard

Bare Copper Conductors (1) |

Conductor

Diameter (nom) mm in |

Insulation

Thickness (nom) mm in |

Nom.

OD mm in |

Bend Radius

Non. Flex (min) mm in |

Finished

Weight (nom) (kg/KM) |

Conductor

Resistance Ω per KM (max) |

| EXRAD-EF125-0.35 | 0.35mm² (37/.11) | 0.79 .031 | 0.26 .010 | 1.30 .051 | 4 .20 | 0.7 | 54.4 |

| EXRAD-EF125-0.50 | 0.50mm2 (41/.13) | 0.89 .035 | 0.28 .011 | 1.50 .059 | 5 .24 | 0.7 | 37.1 |

| EXRAD-EF125-0.75 | 0.75mm² (41/.16) | 1.19 .047 | 0.31 .012 | 1.80 .071 | 7 .28 | 0.9 | 24.7 |

| EXRAD-EF125-1.00 | 1.00mm² (61/.14) | 1.24 .049 | 0.38 .015 | 2.00 .079 | 8 .32 | 1.1 | 18.5 |

| EXRAD-EF125-1.50 | 1.50mm² (84/.15) | 1.55 .061 | 0.38 .015 | 2.30 .091 | 9 .36 | 1.6 | 12.7 |

| EXRAD-EF125-2.0 | 2.00mm² (105/.16) | 1.85 .071 | 0.40 .016 | 2.65 .104 | 11 .41 | 2.2 | 9.42 |

| EXRAD-EF125-2.5 | 2.50mm² (140/.16) | 2.13 .084 | 0.36 .014 | 2.85 .112 | 11 .45 | 2.6 | 7.60 |

| EXRAD-EF125-3.0 | 3.00mm² (161/.152) | 2.26 .089 | 0.46 .018 | 3.20 .126 | 13 .51 | 3.3 | 6.15 |

| EXRAD-EF125-4.0 | 4.00mm² (224/.16) | 2.80 .110 | 0.40 .016 | 3.60 .142 | 14 .57 | 4.1 | 4.71 |

| ISO 19642 Section | Description | Requirement | Typical Results (0.35mm2 Sample) | |

| 4.1.1 | Outside Wire Diameter | 1.40mm max. | 1.34mm | Pass |

| 4.1.2 | Insulation Thickness | 0.20mm min. | 0.27mm | Pass |

| 4.1.3 | Conductor Diameter | 0.90mm max. | 0.76mm | Pass |

| 4.2.1 | Conductor Resistance | 54.4 mΩ/m max. | 46.7 mΩ/m | Pass |

| 4.2.2 | Withstand Voltage | 1kV for 30min // 5kV for 5min. | No dielectric breakdown | Pass |

| 4.2.4 | Insulation Faults | Sparktest @ 3.0kV | No breakdown | Pass |

| 4.2.5 | Insulation Volume Resistivity | 109 Ω /mm min. | 1.21 x 1015 Ω /mm | Pass |

| 5.3.5 | Flexibility Test | Customer-Defined | 34.9 N | NA |

| 5.4.2 | Long-Term Heat Aging | 150°C, 3000 hrs, 3kV, no breakdown | No cracks, No breakdown | Pass |

| 5.4.3 | Short-Term Heat Aging | 175°C, 240hrs, 3kV, no breakdown | No cracks, No breakdown | Pass |

| 5.4.4 | Thermal Overload | 200°C, 6 hrs, 5Kv | No cracks, No breakdown | Pass |

| 5.4.5 | Pressure at High Temperature | Under load @150°C, 5kV 5min, no breakdown | No cracks, No breakdown | Pass |

| 5.4.6 | Shrinkage by heat | 2mm max. @ 150°C | 0.0 mm | Pass |

| 5.4.7 | Low Temperature Winding | 4 hrs @ -40°C, 3kV, no breakdown | No cracks, No breakdown | Pass |

| 5.4.8 | Cold Impact | 16 hrs @ -15°C, 1kV, no breakdown | No cracks, No breakdown | Pass |

| 5.4.9 | Temperature and Humidity Cycling | 40 x 8 hour cycles -40°C to 150°C, relative humidity 80 -100%, 3kV | No cracks, No breakdown | Pass |

| 5.4.10 | Resistance to hot water | 35 days in 85C water, IR not less than 1012 Ω/mm | 4.46 x 1014 Ω/mm, no breakdown | Pass |

| 5.4.11 | Resistance to liquid chemicals | Groups 1 and 2, no breakdown. | All fluids: No crack/damage/breakdown | Pass |

| 5.4.14 | Ozone Resistance | 65°C, 192 hours, Ozone (1+/- 0.05) x 10-6 | No cracks | Pass |

| 5.4.15 | Resistance to Flame Propagation | Must extinguish within 30 sec. max. and a min of 50mm unburned | 4.0 sec. | Pass |